PLM Innovation and the Digital Twin

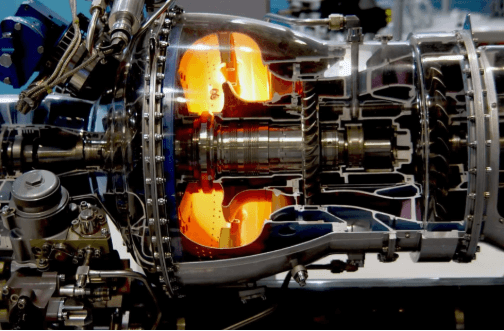

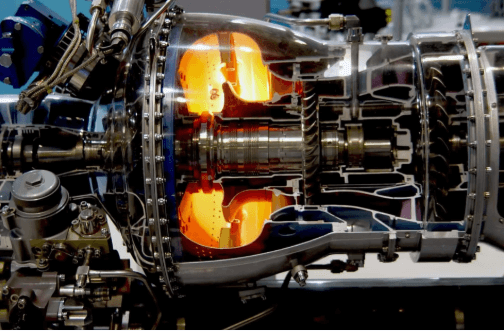

Digital Twin encompasses more than the images captured from the product design i.e. 3D CAD models and the 2D drawings. It also includes all of the technical specifications, the associated manufacturing information, the servicing requirements, quality and maintenance requirements and eventually can lead to predictive maintenance. All these things are now possible via the so called Internet of Things. Service and leasing of expensive products is particularly relevant within the aerospace industry for example aircraft engines and associated technologies.

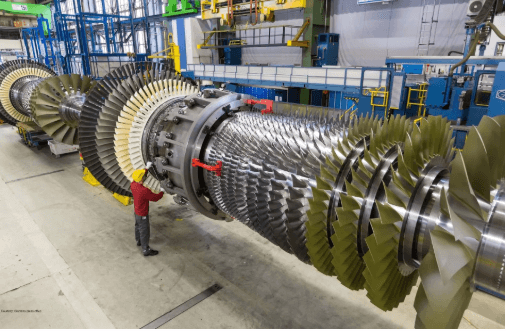

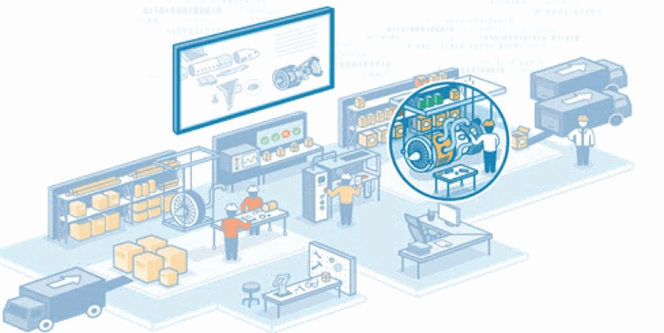

Logistics and the transport of products, packaging replenishment, distribution and even Warehousing, is becoming part of the complete management life cycle of a product. PLM and the Digital Twin is now capable of supporting the product in all of these contexts. Now with smarter more sophisticated products these digital representations of the product and associated technical data can be readily seen via convenient smart portable devices or walk through scenes for products of a grander scale, e.g. marine and turbine generators.

Accelerating change and rapid exchange of data is now required and with the growing use of Cloud technology and The Internet Of Things

A fundamental part of product development and manufacturing is the product lifecycle. By now we all realise that a product lifecycle can be considered as a sequence of product development stages from early product design it's eventual manufacture, market introduction and continual support through growth, maturity and decline. As a product goes through these stages, it requires a variety of activities: product requirements, new product introductions, engineering changes, manufacturing, re-fabrication, disposal, and other adjustments. Some products have a short lifespan (consumer goods, electronics) and others stay in active operation more than 50 years (aircraft and defense systems).

More on PLM Innovation and the Digital Twin

As mentioned Digital twinning bridges physical products with intelligent virtual replicas, the technology is being embraced across a wide industrial sector. This gives developers earlier and more predictable insights of how the physical product will perform and the ability to detect potential problems. Whether the twin is serving as a prototype or as a digital counterpart to a physical device, having the ability to simulate operation and functionality before deployment is a huge advantage. It saves time and costly rework by giving design, manufacturing and test engineers early opportunities to examine and predict how the product will eventually work. All this can be achieved before committing costly time and resources in building products that may eventually fail. Risk and development lead times can be reduced before actually deploying the product.

From Design to Factory floor PLM and the Digital Twin is here to stay and is the way Companies can remain competitive, with design and manufacture resource located across the globe, often thousands of miles apart. PLM if deployed and supported correctly can bring huge business benefits.

PLM projects can be part of a business change strategy or improving upon already existing PLM technologies in your business, often requiring a more focused technical level support from an independent PLM vendor who can provide the unbiased help you are seeking. Whatever the need might be there are recognised approaches and associated management from installation, user acceptance testing, early life support and knowledge transfer into the business.

Working via our offices close to Birmingham airport we are able to support your PLM business requirements no matter how diverse or how challenging, whether remotely or on premise.